#281: 10 Years of Make in India | Summary

Read this 58-sec blog for a comprehensive report on Make in India.

10 years of Make in India - a quick look at what did it solve for India?

Aim: Boost manufacturing + attract FDI + Jobs

A look at successes and pertaining challenges!

The Wins of Make in India 🌟

Increased FDI

2014-2023: $600bn+ FDI fueling tech & industrial sectors like IT, Telcom, pharma, automobilesManufacturing Growth

Product Linked Incentive like scheme boosted domestic manufacturing making India 2nd largest mobile phone manufacturer while increasing automobile export.Defense Sector Boost

Indigenization focus led to higher domestic procurement w/ 5x defense exports in 2022Infrastructure Development

Delhi-Mumbai Industrial Corridor, Sagarmala etc. projects aimed to reduce costs & enhance competitiveness with progress in smart cities & industrial zonesIndia: Export Hub

$16 billion electronics export by 2022; Key PPE exporter during the COVID-19 pandemic

Startup Ecosystem & MSMEs

MSMEs contributed 30% to GDP while benefiting from modernization incentivesAutomotive & EV Growth

Green mobility via PLI for EVs/batteriesTextile Sector Revival

$44bn exports in Textile & apparel exports supported by PLI incentives & global investmentsPharmaceutical Manufacturing

Stronger image as “pharmacy of the world” with vaccine production

The Losses of Make in India ⚠️

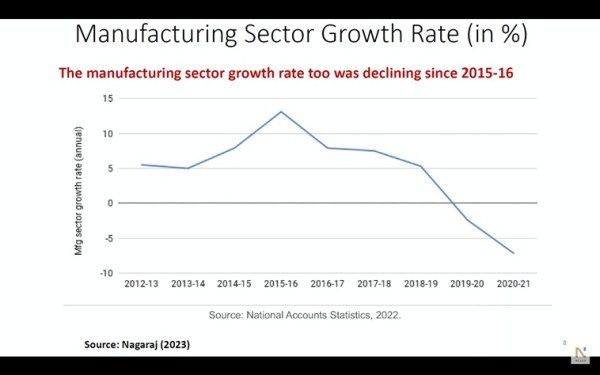

Stagnant Manufacturing Growth

Manufacturing’s share of GDP remained around 15-17%, below the targeted 25%.Job Creation Shortfall

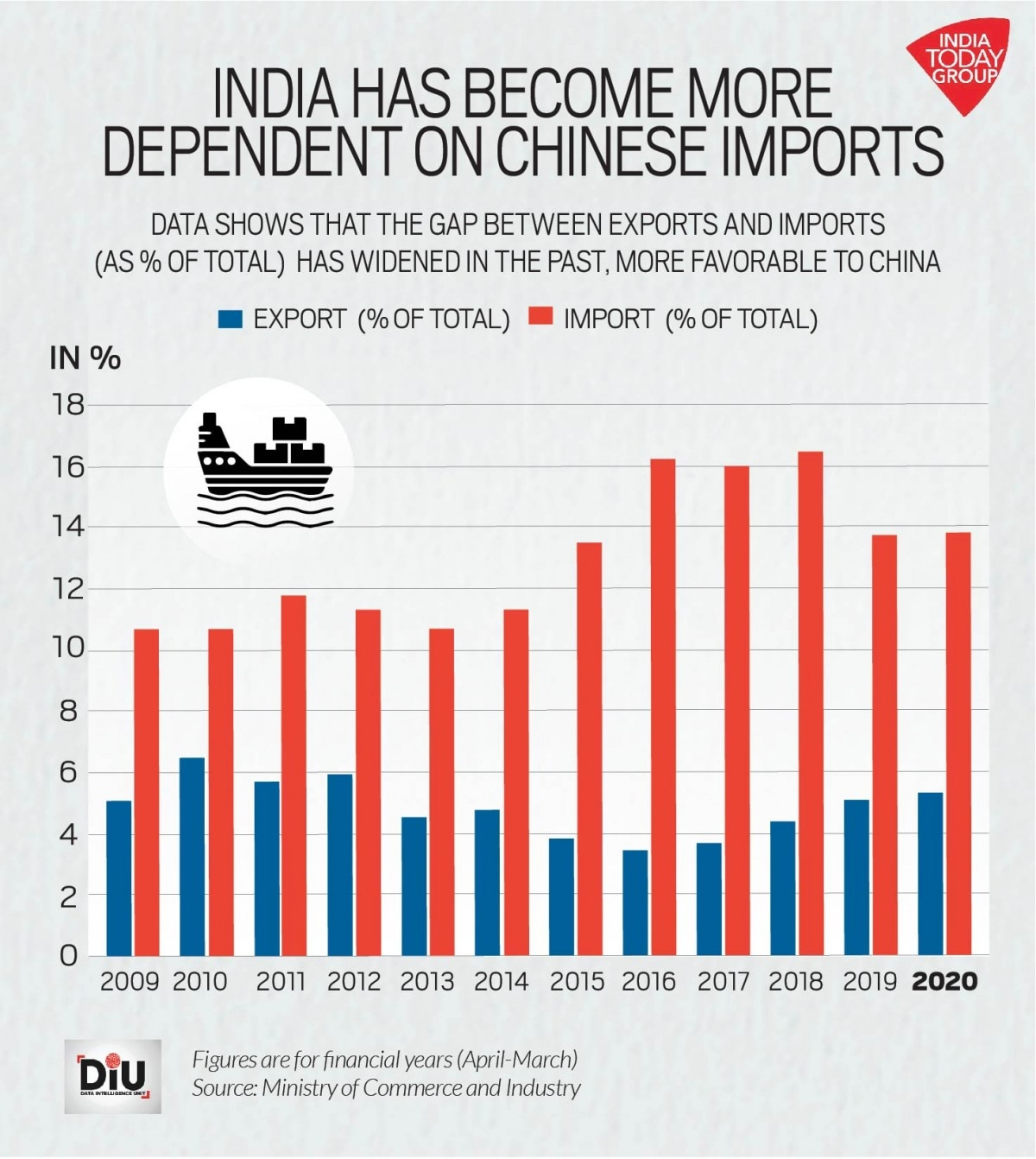

<10 mn jobs created, far short of 100mn goal owing to automation & skills gapHigh Import Dependency

High import on e-components & Lithium-ion batteries limiting self relianceLow Private Investment

Private sector investments lagged, with COVID-19 disrupting supply chains and credit constraints limiting large-scale projects.Bureaucratic Delays

Land acquisition and project approval delays hampered progress, with significant setbacks in projects like the DMIC.Underperformance in Key Sectors

India lost market share to competitors like Vietnam in textiles, and defense imports remain high.Infrastructure Challenges

Logistical bottlenecks and power shortages hinder manufacturing growth, making India less competitive.MSME Struggles

MSMEs faced challenges from demonetization, GST implementation, and cheaper imports, especially from China.Global Trade Limitations

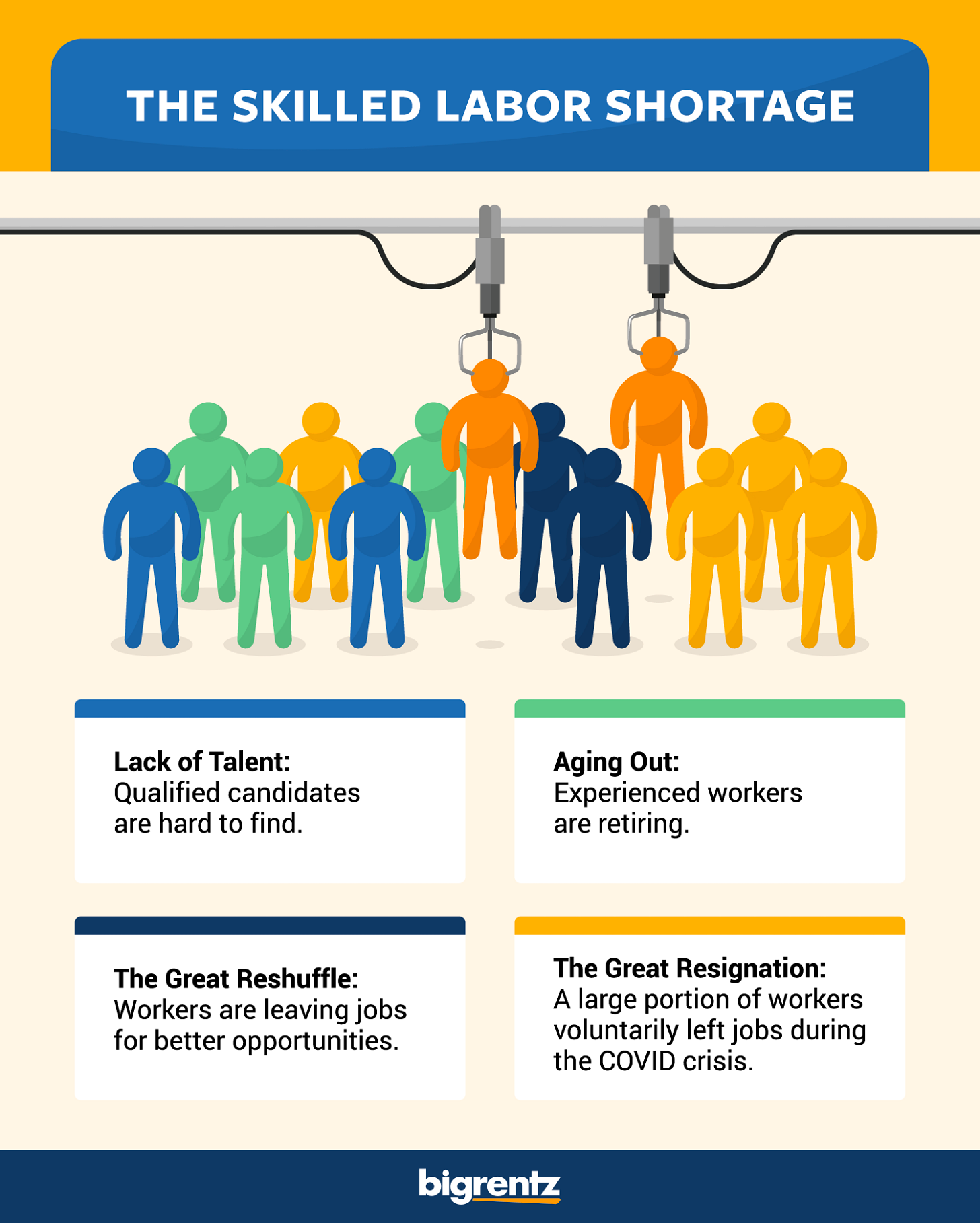

India’s withdrawal from RCEP and trade disruptions limited access to global markets and supply chains.Skilled Labor Shortage

Only 2.3% of India’s workforce has formal training, leaving gaps in advanced manufacturing sectors.Environmental Concerns

Rapid industrial growth has raised environmental concerns, with inadequate assessments and reliance on coal energy.Unmet Renewable Energy Targets

In 2023, 70% of solar panel requirements were still imported, despite efforts to increase domestic production.Limited R&D Investment

R&D spending remains low at 0.7% of GDP, limiting innovation in sectors like electronics and pharmaceuticals.

Conclusion

Make in India achieved significant progress in FDI, manufacturing, and exports.

However, challenges like job creation, infrastructure, and import dependency persist. Future efforts should focus on innovation, labor shortages, and ease of business to fulfill its potential.

Prepare to be part of India's growth story. Follow @CSEWhy on Twitter.